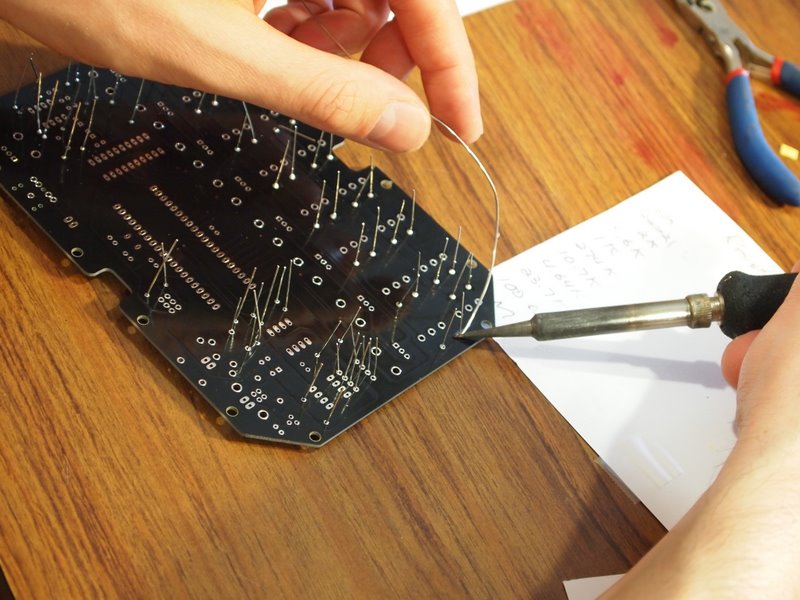

Lead or lead-free – Solder is generally a combination of metals, which are chosen for the best reliability and conductivity.While there is a large variety of different types of solder, at the most basic, you need to choose between lead or lead-free, the diameter of the wire, flux core or solid wire, and the type of flux. With a soldering station, the soldering iron plugs into the station for greater control over temperature, and other features like set-temperature memory, lock-out, etc. On the low end, most appropriate for hobbyists, a soldering iron may plug directly into the electrical wall outlet, which provides no control over soldering iron temperature. What is the difference between a soldering iron and a soldering station? These include soldering tips, which are metal slugs that rest against the heating element, and others which are integrated with the heating element in a cartridge. It also has iron plating to protect the soft, corrosive-prone copper from flux and solder, and chrome-nickel plating to keep the flux from wetting up the tip.īeyond that, there are options that provide better control over the soldering iron temperature and heat response (time it takes to heat up again after soldering). It has a copper interior, which acts as an effective and efficient thermal conductor. The soldering tip’s job is to transfer heat from the heating element to the work. At its simplest form, it consists of a metal tip, a heating element that brings the tip up to soldering temperature, an insulated handle to allow safe holding of the soldering iron, and a plug for either a wall outlet or the soldering station. Flux, if the wire solder does not include a flux core or if additional flux is needed.Ī soldering iron is a hand tool used to solder two metal surfaces together.Wire solder, with or without a flux core.A soldering iron capable of reaching the melting point of the solder.When soldering an electronic connector to a contact point (often called a “pad”), you generally need the following:

Hand soldering is the process of soldering one connection (called “solder joint”) at a time, as opposed to more automated soldering processes such as wave soldering (for thru-hole components) or reflow soldering (for SMT components). Flux is used to clean and prep the surfaces, which allows the melted solder to flow (or “wet”) and bond with the metal surfaces. The solder is melted using a soldering iron. It also provides electrical continuity, so that the electronic signal can travel through the connection without interruption. Solder secures the connection so it doesn’t break loose due to vibration or other mechanical forces. Soldering is the joining of two metal surfaces mechanically and electrically, with the use of metal called solder.

0 kommentar(er)

0 kommentar(er)